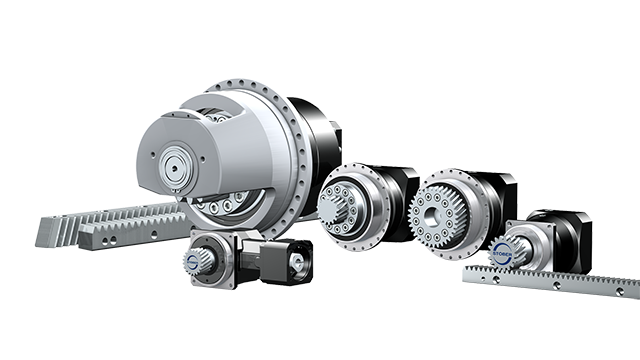

Rack and Pinion Drives

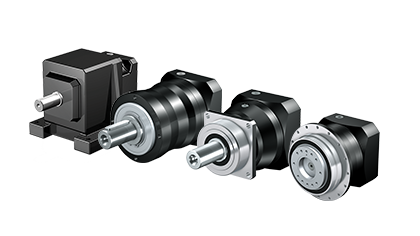

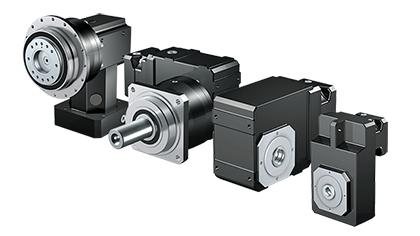

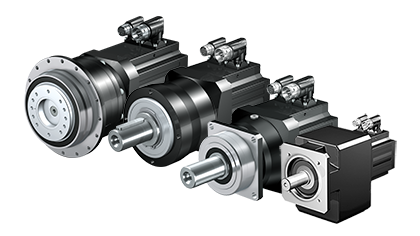

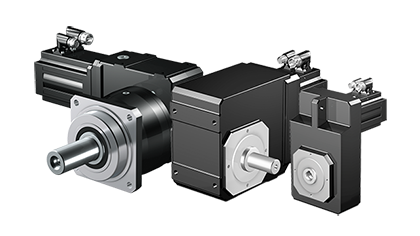

From high speed to high force, flange to shaft, STOBER has the options you need. Every rack and pinion system uses STOBER’s superior servo gear units and can be made into system with a motor. These pinions work with a variety of rack options, including helical or straight tooth.

- High Speed or High Force

- ZR: For high speed applications

- ZTR: For compact applications requiring high force

- ZTRS: For applications requiring extreme force

- ZV: For flexibility and economy

Improve your machine’s repeatability with high stiffness.

The rack and pinion offerings can be mated to both flange gearboxes as well as shafted inline or right angle options. Selection and calculations are done by STOBER for a completely engineered solution.

- ZR: For high speed applications

- ZTR: For compact applications requiring high force

- ZTRS: For applications requiring extreme force

- ZV: For flexibility and economy

Power Density:

|

|||||

|

Price Range:

|

$ | $ | $ | $ | $ |

- Acceleration Feed Force: 2.1- 15 kN

- Feed Velocity: .23 – 6.7 meters/second

- Module: 2 – 4 mm

- Number of teeth: 26 – 45

- Backlash: 10 – 56 μm

Find your right fit!

Power Density:

|

|||||

|

Price Range:

|

$ | $ | $ | $ | $ |

- Acceleration Feed Force: 5.8 – 67 kN

- Feed Velocity: .09 – 4.7 meters/second

- Module: 2 – 8 mm

- Number of teeth: 12 – 32

- Backlash: 4 – 44 μm

Find your right fit!

Power Density:

|

|||||

|

Price Range:

|

$ | $ | $ | $ | $ |

- Acceleration Feed Force: 16 – 126 kN

- Feed Velocity: .06 – 4.7 meters/second

- Module: 2 – 10 mm

- Number of teeth: 15 – 32

- Backlash: 7 – 70 μm

Find your right fit!

Power Density:

|

|||||

|

Price Range:

|

$ | $ | $ | $ | $ |

- Acceleration Feed Force: 1.3 – 15 kN

- Feed Velocity: .06 – 5.3 meters/second

- Module: 2 – 4 mm

- Number of teeth: 16 – 25

- Backlash: 8 – 123 μm

Find your right fit!

- ZR: For high speed applications

- ZTR: For compact applications requiring high force

- ZTRS: For applications requiring extreme force

- ZV: For flexibility and economy

- Bearings: Options for axial or radial loads

- Standard – ball bearing ideal for some axial and radial load capacity

- Reinforced bearing – ideal for high axial loads

- Backlash:

- Standard

- Reduced

- Available with a geared motor

Find your right fit!

- Bearings: Options for axial or radial loads

- Standard – ball bearing ideal for some axial and radial load capacity

- Reinforced bearing – ideal for high axial loads

- Backlash:

- Standard

- Reduced

- Available with a geared motor

Find your right fit!

- Gear:

- Standard gear

- Felt gear – simplify lubrication

- Backlash:

- Standard

- Reduced

- Available with a geared motor

Find your right fit!

- ZV with P Series

- Pinion Position:

- Shaft end

- Shaft shoulder

- Bearings: Options for axial or radial loads

- Standard – ball bearing ideal for some axial and radial load capacity

- Double row angular contact bearing – ideal for high axial loads

- Backlash:

- Standard

- Reduced

- Pinion Position:

- ZV with PE Series

- Pinion Position:

- Shaft end

- Shaft shoulder

- Pinion Position:

- ZV with KS Series

- Pinion Position:

- Shaft end

- Shaft shoulder

- Pinion Position:

- ZV with K/KL Series

- Pinion Position:

- Shaft end

- Shaft shoulder

- Housing Style:

- Pitch circle diameter tapped holes

- Foot mounting

- Pinion Position:

- Available with a geared motor

Find your right fit!

- Fuselage

- Wing assembly

- Drilling and Riveting

- Machine Tool

- Automated Guided Vehicles (AGV)

- Carbon Fiber Placement

- Testing and Inspection

- Space Tracking Systems

- Assembly Turn Tables

- Linear Press

- Robotics Auxiliary Axis

- Palletizing

- Automated Assembly

- Custom Assembly Machines

- Radar

- Pipe and Wire Bending

- Carbon Fiber Production

- Electronics Assembly

- Index Tables

- Machining

- Metal Cutting & Bending

- Pick and Place

- Robotic Auxiliary

- Tire Manufacturing

- Transfer Lines

- Carbon fiber tape laying

- Horizontal and vertical mills

- Flame, laser, waterjet, and plasma cutting

- Grinding

- Indexing

- Bending and forming

- Automated Guided Vehicles (AGV)

- Automated Vehicle Parking

- Conveyors

- Line Diverter

- Linear Transfer

- Palletizing

- Pick and Place

- Sorting/Diverting

- Storage and Retrieval

- Delta

- Pick and Place

- Auxially axis

- Telescoping arms

- Positioning axis

[TABS_R id=9371]

| Title | Version | ID | Date | Size | |

|---|---|---|---|---|---|

| No results were found. | |||||

| Title | Version | ID | Date | Size | |

|---|---|---|---|---|---|

| No results were found. | |||||

| Title | Version | ID | Date | Size | |

|---|---|---|---|---|---|

| No results were found. | |||||

| Title | Version | ID | Date | Size | |

|---|---|---|---|---|---|

| No results were found. | |||||

| Title | Version | ID | Date | Size | |

|---|---|---|---|---|---|

| No results were found. | |||||

Contact us!

Phone: +1 (888) 786-2371

Email: sales@stober.com

With a few simple clicks, you can download drawings, technical data sheets, or dimensional drawings of any STOBER product. Plus, you can easily request a quote.

Are you looking for CAD data? With the STOBER CAD tool, you can download the drawings you want with just a few clicks.

STOBER CADWith SERVOsoft® we provide you with a tool that you can use to precisely scale your drive systems in just a few steps. Electrically and mechanically. And it’s quick and easy too.

SERVOSOFT®Our sales reps have the expertise and industry know-how to provide you with the best solutions. Call to get more information today!

Find your RepDo you need competent help with spare parts, replacement drives, repairs and retrofitting? Please contact us! We also offer you a 24-hour emergency call for urgent cases.

Aftermarket ServiceEmergency SupportSTOBER offers emergency application and installation support 24 hours a day, 7 days a week, 365 days a year anywhere in the US. We are here for you!

STOBER’s regional sales team will be with you every step of the way. From sizing to ordering to aftermarket, our engineers will help you optimize your solution.