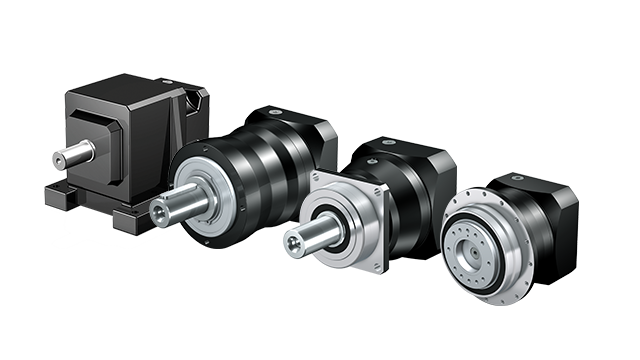

Inline Servo Gear Units

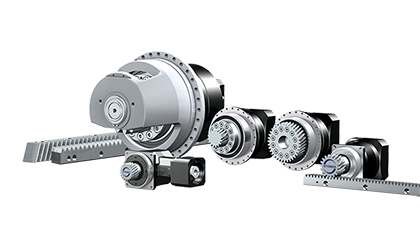

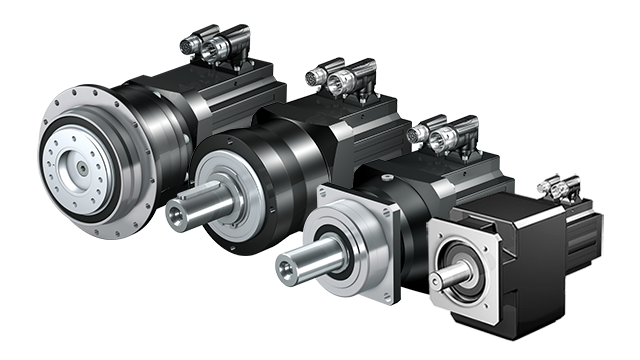

STOBER servo inline gear units are unrivaled in their precision and options. Choose from planetary gearing or take advantage of helical gearing. Servo doesn’t have to mean planetary!

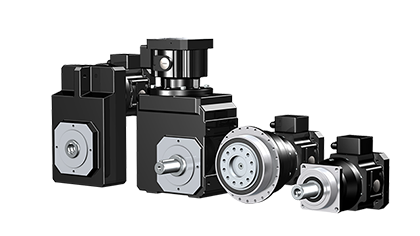

These gear units can be mounted to any motor with our toleranced motor adapters or you can add a STOBER motor on them to make a geared motor. These units are assembled in our Maysville, Kentucky facility, shipped in one day, and come with a 5 year warranty.

- Performance. Precise. Perfect fit.

- P: For high precision and smoothness

- C: For mounting flexibility

- PH: For high stiffness and performance

- PE: For economic applications

- PHQ: For maximum power and rigidity

Choose from planetary gearing or helical bevel. With options for bearings or reduced backlash, we can optimize our products to match your application.

It is incredibly efficient, has low backlash, and runs quiet.

Plus, you can choose from several bearing options to handle radial or axial loads, optimizing your machine design.

P gearboxes are available as compact planetary servo geared motors or they can be mounted to any motor with our toleranced motor adapter.

Choose the housing style that fits your application – round or square flanges, tapped holes, or foot mounting.

C gearboxes are available as compact planetary servo geared motors or they can be mounted to any motor with our toleranced motor adapter.

It offers a reinforced bearing option for applications with higher axial loads.

PH gearboxes are available as compact planetary servo geared motors or they can be mounted to any motor with our toleranced motor adapter.

Its unique for an economy option because it utilizes helical gearing.

PE gearboxes are available as compact planetary servo geared motors or they can be mounted to any motor with our toleranced motor adapter.

It provides smooth operation while producing huge amounts of torque.

PHQ gearboxes are available as compact planetary servo geared motors or they can be mounted to any motor with our toleranced motor adapter.

- P: For high precision and smoothness

- C: For mounting flexibility

- PH: For high stiffness and performance

- PE: For economic applications

- PHQ: For maximum power and rigidity

Power Density:

|

|||||

|

Price Range:

|

$ | $ | $ | $ | $ |

- Total gear ratio range: 3 – 100

- Acceleration torque: 11 – 3,450 Nm

- Nominal torque: 16 – 2,483 Nm

- Continuous Input Speed: Up to 6,000 RPM

- Cyclic Input Speed: Up to 8,000 RPM

- Torsional Stiffness: Up to 407 Nm/arcmin

Find your right fit!

Power Density:

|

|||||

|

Price Range:

|

$ | $ | $ | $ | $ |

- Total gear ratio range: 2 – 276

- Acceleration torque: 36 – 8,000 Nm

- Nominal torque: 35 – 7,000 Nm

- Continuous Input Speed: Up to 4,000 RPM

- Cyclic Input Speed: Up to 7,000 RPM

- Torsional Stiffness: Up to 393 Nm/arcmin

Find your right fit!

Power Density:

|

|||||

|

Price Range:

|

$ | $ | $ | $ | $ |

- Total gear ratio range: 4 – 121

- Acceleration torque: 60 – 7,500 Nm

- Nominal torque: 36 – 5,000 Nm

- Continuous Input Speed: Up to 6,000 RPM

- Cyclic Input Speed: Up to 8,000 RPM

- Torsional Stiffness: Up to 1,743 Nm/arcmin

Find your right fit!

Power Density:

|

|||||

|

Price Range:

|

$ | $ | $ | $ | $ |

- Total gear ratio range: 3 – 100

- Acceleration torque: 13 – 310 Nm

- Nominal torque: 7 – 160 Nm

- Continuous Input Speed: Up to 4,000 RPM

- Cyclic Input Speed: Up to 8,000 RPM

- Torsional Stiffness: Up to 35 Nm/arcmin

Find your right fit!

Power Density:

|

|||||

|

Price Range:

|

$ | $ | $ | $ | $ |

- Total gear ratio range: 5.5 – 600

- Acceleration torque: 200 – 43,000 Nm

- Nominal torque: 100 – 25,000 Nm

- Continuous Input Speed: Up to 4,500 RPM

- Cyclic Input Speed: Up to 8,000 RPM

- Torsional Stiffness: Up to 6,269Nm/arcmin

Find your right fit!

- P: For high precision and smoothness

- C: For mounting flexibility

- PH: For high stiffness and performance

- PE: For economic applications

- PHQ: For maximum power and rigidity

- Output Shaft:

- Plain shaft

- Feather key

- Bearings: Options for axial or radial loads

- Standard – ball bearing ideal for some axial and radial load capacity

- Double row angular contact bearing – ideal for high axial loads

- Cylindrical roller bearing – ideal for radial loads

- Backlash:

- Standard

- Reduced

- Package Options: options for different environments. A package includes coating, lubrication, and output material

- Standard Duty – RAL-9005 black paint, Synthetic Exxon Mobil SHC 629, carbon steel output

- Food Duty – 316 stainless steel epoxy paint with anti-microbial clear coat, Exxon Mobil SHC CIBUS 220, and stainless steel output

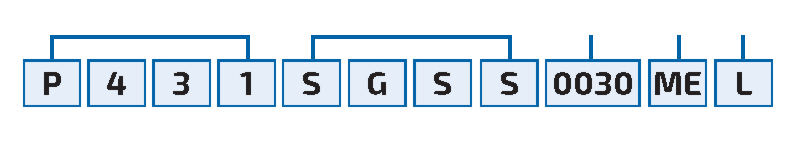

- Motor Adapter:

- ME – standard clamp coupling

- Seal option – MSS1 seal for longer life

- MEL – clamp coupling that can accommodate larger diameter motor shaft without upsizing to larger gearbox

- MF – flexible coupling, ideal for thermal length compensation

- MFL – flexible coupling that can accommodate larger diameter motor shaft without upsizing to a larger gearbox

- MB – ServoStop with integrated safety brake

- ME – standard clamp coupling

- Environmental Considerations: ATEX Certified Available for explosive environments

- Available as a geared motor!

- Available as a rack and pinion system

Find your right fit!

- Housing Styles:

- Round output flange

- Pitch circle diameter tapped holes

- Foot mounting

- Square output flange

- Package Options: options for different environments. A package includes coating, lubrication, and output material

- Standard Duty – RAL-9005 black paint, Synthetic Exxon Mobil SHC 629, carbon steel output

- Corrosion Resistant Duty – 316 stainless steel epoxy paint, Exxon Mobil SHC 630 or 600XP220 Mineral, and stainless steel output

- Food Duty – 316 stainless steel epoxy food duty paint with anti-microbial clear coat, Exxon Mobil SHC CIBUS 220, and stainless steel output

- Motor Adapter:

- ME – standard clamp coupling

- Seal option – MSS1 seal for longer life

- MB – ServoStop with integrated safety brake

- ME – standard clamp coupling

- Environmental Considerations: ATEX Certified Available for explosive environments

- Mounting Positions:

- EL1, 2, 3, 4, 5, or 6

- Available as a geared motor!

Find your right fit!

- Bearings: Options for axial or radial loads

- Standard – ball bearing ideal for some axial and radial load capacity

- Reinforced bearing – ideal for high axial loads

- Backlash:

- Standard

- Reduced

- Coating Options: options for different environments.

- Standard Duty – RAL-9005 black paint

- Washdown Duty – 316 stainless steel epoxy paint

- Motor Adapter:

- ME – standard clamp coupling

- Seal option – MSS1 seal for longer life

- MF – flexible coupling, ideal for thermal length compensation

- MB – ServoStop with integrated safety brake

- ME – standard clamp coupling

- Environmental Considerations: ATEX Certified Available for explosive environments

- Available as a geared motor!

- Available as a rack and pinion system

Find your right fit!

- Coating Options: options for different environments.

- Standard Duty – RAL-9005 black paint

- Washdown Duty – 316 stainless steel epoxy paint

- Motor Adapter:

- MA – standard clamp coupling

- MAL – clamp coupling that can accommodate larger diameter motor shaft without upsizing to larger gearbox

- Available as a geared motor!

- Available as a rack and pinion system

Find your right fit!

- Bearings: Options for axial or radial loads

- Standard – ball bearing ideal for some axial and radial load capacity

- Reinforced bearing – ideal for high axial loads

- Backlash:

- Standard

- Reduced

- Coating Options: options for different environments.

- Standard Duty – RAL-9005 black paint

- Washdown Duty – 316 stainless steel epoxy paint

- Motor Adapter:

- ME – standard clamp coupling

- Seal option – MSS1 seal for longer life

- MF – flexible coupling, ideal for thermal length compensation

- MB – ServoStop with integrated safety brake

- ME – standard clamp coupling

- Environmental Considerations: ATEX Certified Available for explosive environments

- Available as a geared motor!

- Available as a rack and pinion system

Find your right fit!

- Aerospace

- Automation

- Automotive Manufacturing

- Beverage

- Converting & Printing

- Energy

- Entertainment

- Food Processing

- Machine Tool

- Material Handling

- Packaging

- Robotics

- Semiconductor

- Fuselage

- Wing assembly

- Drilling and Riveting

- Machine Tool

- Automated Guided Vehicles (AGV)

- Carbon Fiber Placement

- Testing and Inspection

- Space Tracking Systems

- Assembly Turn Tables

- Linear Press

- Robotics Auxiliary Axis

- Palletizing

- Automated Assembly

- Custom Assembly Machines

- Radar

- Pipe and Wire Bending

- Carbon Fiber Production

- Electronics Assembly

- Index Tables

- Machining

- Metal Cutting & Bending

- Pick and Place

- Robotic Auxiliary

- Tire Manufacturing

- Transfer Lines

- Accumulation

- Casing (Packaging)

- Cleaner

- Closer/Capper/Seamer

- Conveying

- Depalletizer

- Filler

- Inspection/Detecting

- Palletizer

- Cutting

- Tension Control

- Web Lines

- Winding

- Paper Converting

- Woven Products

- 3D Printing

- Electronics Printing

- Labels

- Flexographic

- Circuit Boards

- Sheet

- Ball, Gate, and Globe Valves

- Throttle/Governor Valves

- Chokes

- Process Valves

- ATEX Explosion Proof Gear Units

- Animatronics

- Backdrops

- Staging

- Theme parks

- Simulators for aerospace, automotive, locomotive, theme park rides and more

- Augers

- Bone saws

- Choppers

- Cone lines

- Conveyors

- Deboning

- Grinders

- Kill Table

- Metal detection

- Mixing

- Overhead drives

- Palletizing

- Pumps

- Tenderizing

- Carbon fiber tape laying

- Horizontal and vertical mills

- Flame, laser, waterjet, and plasma cutting

- Grinding

- Indexing

- Bending and forming

- Automated Guided Vehicles (AGV)

- Automated Vehicle Parking

- Conveyors

- Line Diverter

- Linear Transfer

- Palletizing

- Pick and Place

- Sorting/Diverting

- Storage and Retrieval

- Case Erectors

- Converting (Printing/Diaper/Labeling)

- Fillers

- Food Packaging

- Package Manufacturing (Bag, Pouch, etc.)

- Palletizing

- Sealers

- Sorting

- Straight Line OR Rotary

- Stuffers

- Wrappers

- Delta

- Pick and Place

- Auxially axis

- Telescoping arms

- Positioning axis

- Chemical mechanical planarization (CMP)

- Wafer manufacturing/processing

- Surface conditioning

- Expose and write

- Etching

- Ion implant

- Sputter

- Chemical Vapor Deposition (CVD)

- Inspection Measurement

- Assembly and Packaging

- Testing

[TABS_R id=9371]

| Title | Version | ID | Date | Size | |

|---|---|---|---|---|---|

| No results were found. | |||||

| Title | Version | ID | Date | Size | |

|---|---|---|---|---|---|

| No results were found. | |||||

| Title | Version | ID | Date | Size | |

|---|---|---|---|---|---|

| No results were found. | |||||

Contact us!

Phone: +1 (888) 786-2371

Email: sales@stober.com

With a few simple clicks, you can download drawings, technical data sheets, or dimensional drawings of any STOBER product. Plus, you can easily request a quote.

Are you looking for CAD data? With the STOBER CAD tool, you can download the drawings you want with just a few clicks.

STOBER CADWith SERVOsoft® we provide you with a tool that you can use to precisely scale your drive systems in just a few steps. Electrically and mechanically. And it’s quick and easy too.

SERVOSOFT®Our sales reps have the expertise and industry know-how to provide you with the best solutions. Call to get more information today!

Find your RepDo you need competent help with spare parts, replacement drives, repairs and retrofitting? Please contact us! We also offer you a 24-hour emergency call for urgent cases.

Aftermarket ServiceEmergency SupportSTOBER offers emergency application and installation support 24 hours a day, 7 days a week, 365 days a year anywhere in the US. We are here for you!

SUPPORT YOU CAN COUNT ON

STOBER’s regional sales team will be with you every step of the way. From sizing to ordering to aftermarket, our engineers will help you optimize your solution.