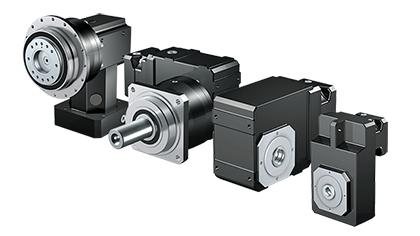

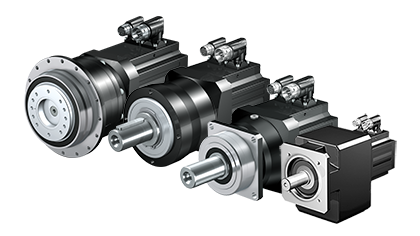

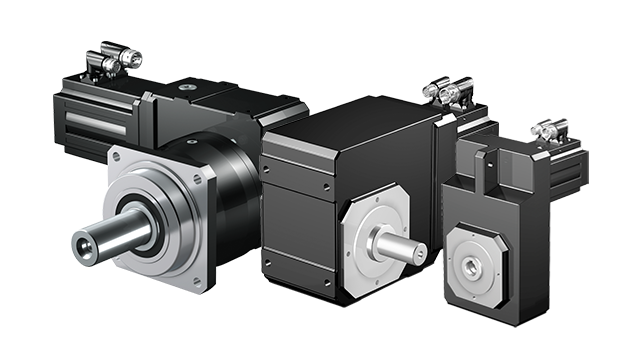

Right Angle Geared Motors

STOBER servo right-angle geared motors are available as planetary right-angle geared motors and helical-bevel geared motors. All drive units are provided with high-quality helical gearing for unrivalled smoothness of running and backlash stability. Backlash down to ≤1.5 arcmin. Super compact synchronous servo motors are ideal for highly dynamic applications.

[wptabs id=”19094″]