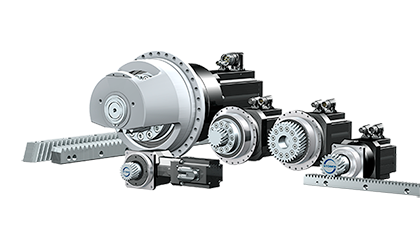

Rack and Pinion Drive Sytems

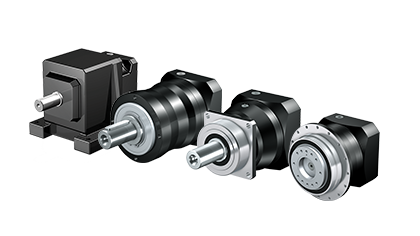

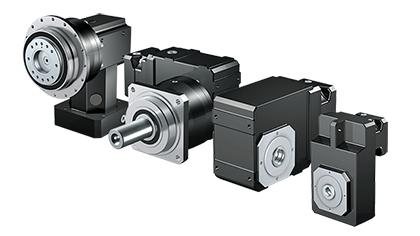

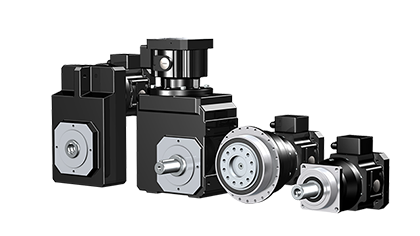

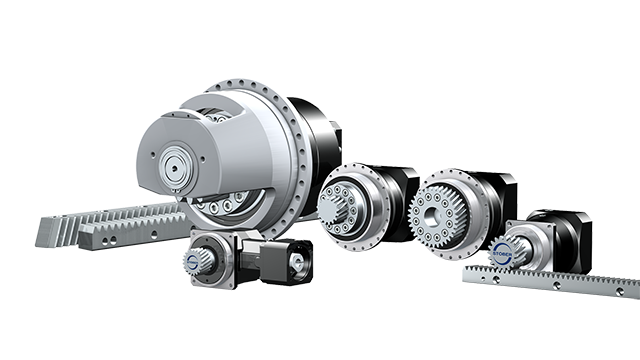

From high speed to high force, flange to shaft, STOBER has the options you need, especially when it comes to rack and pinion drives. Every rack and pinion system uses STOBER’s superior servo gear units and can be made into a system with a motor. These pinions work with a variety of rack options, including helical or straight tooth.

The versatility of our rack and pinion drive systems makes them indispensable across a broad spectrum of industries. Examples of our products can be found in the packaging, beverage, food processing, automotive, printing, and material handling sectors, among others. All of our rack and pinion drive systems are available as compact servo or geared motors, adding to their adaptability. Additionally, they can be mounted to any motor featuring our tolerance motor adapter. If our standard systems don’t fit exactly into a customer’s existing setup, we also have the capability to design customized solutions that will.

[wptabs id=”19390″]

| Title | Version | ID | Date | Size | |

|---|---|---|---|---|---|

| No results were found. | |||||

| Title | Version | ID | Date | Size | |

|---|---|---|---|---|---|

| No results were found. | |||||

| Title | Version | ID | Date | Size | |

|---|---|---|---|---|---|

| No results were found. | |||||

STOBER Rack and Pinion

STOBER Configurator