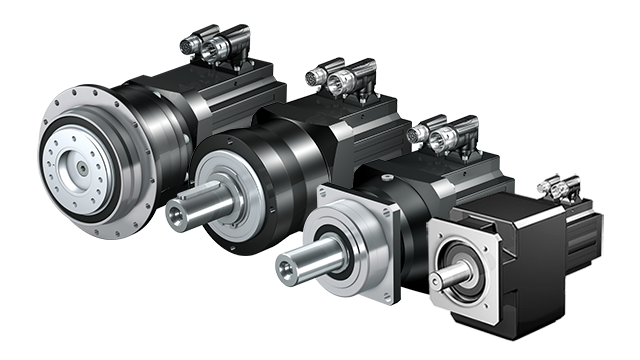

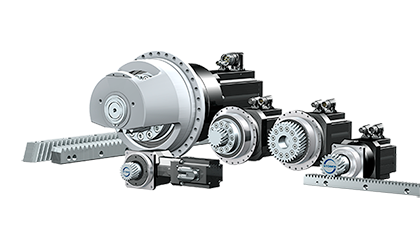

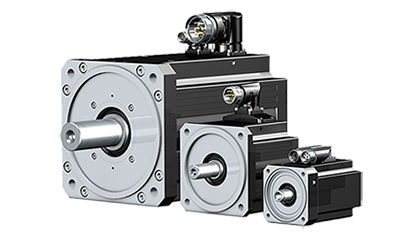

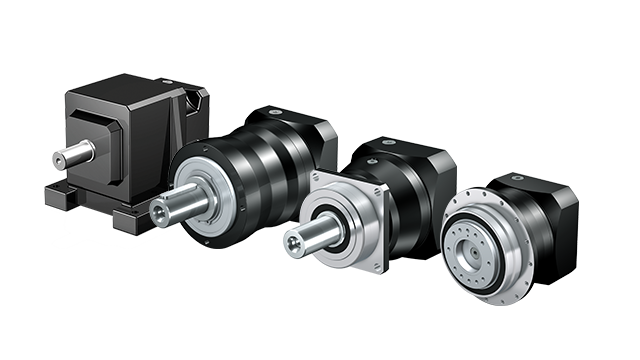

Synchronous Servo Inline Gear UNITs

STOBER synchronous servo inline geared motors: The range you need.

These motors are available as planetary geared motors and as helical geared motors. Compact. Dynamic. Cooler. Adaptable. Packed with the STOBER guarantee – unparalleled service and support and an unmatched warranty of two years!

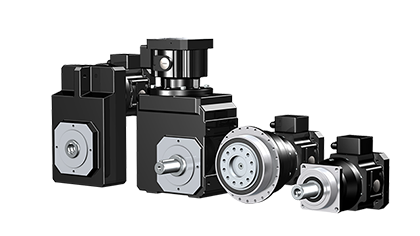

These motors are designed specifically to tackle some of the most rugged applications across multiple industries. They can be found in equipment used for aerospace manufacturing, automated production systems, beverage processing, printing operations and more. In addition to these standard models, we have the expertise and knowledge necessary to create fully customized solutions for your specific needs no matter what they may be.

We take pride in our ability to solve problems for our customers, creating the ideal solutions for their situations. Our experts work closely with you to identify your pain points and deliver a system that resolves them as thoroughly and effectively as possible.

[wptabs id=”19020″]

| Title | Version | ID | Date | Size | |

|---|---|---|---|---|---|

| No results were found. | |||||

| Title | Version | ID | Date | Size | |

|---|---|---|---|---|---|

| No results were found. | |||||

| Title | Version | ID | Date | Size | |

|---|---|---|---|---|---|

| No results were found. | |||||