How to Save Millions on Gearbox Inventory – Optimize Your Storeroom

Do you know that most companies have $1 million in their plants they can’t use? Where is it? Simply put, it’s in the storeroom. It takes a lot of time, money and space to stock it, maintain it, and manage it. In our series called, STOBER’s Power Tips, we share insight on how you can get this money back.

The importance of your storeroom

A storeroom is truly an insurance policy. As you know, your plant runs 24 hours a day, 7 days a week. Downtime is an extremely costly issue. Many customers lose thousands of dollars a minute when production lines are down. When a component, such as a bearing or a gearbox fails, your maintenance team needs to quickly access replacements in order to get production up and running. Having a storeroom with these critical components is a necessity that unfortunately ties up financial resources

However, predicting when a component will fail is difficult. This means many stocked components go unused for so long that their warranties expire, and you have wasted money on something you never even used.

How to optimize your storeroom to reclaim money

But what if there were ways to simplify what was needed in the storeroom? What if you could optimize your storeroom to reclaim some of the money sitting idly on your shelves? Let’s look at three tips for optimizing your gear reducer inventory.

- First, work with suppliers that have short deliveries. Waiting weeks or months for a product means you need to have several in stock at any given time. If you can find a partner with fast turnaround times, there is no need to stock as many reducers.

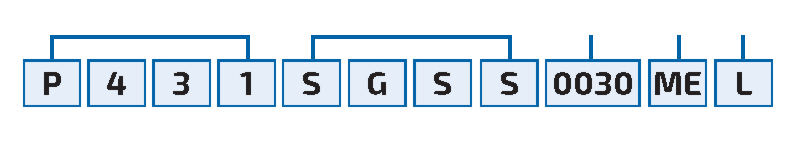

- Second, purchase units with flexible options. For example, look for reducers that can be mounted in multiple orientations or that can accommodate several machine shaft sizes. This allows you to minimize the number of gear reducers you need since several can be used in multiple line locations.

- Finally, standardize on what reducers your lines need. We find that many companies have a variety of ratios on the production floor. This means numerous reducers must be stocked. By spending a little time doing a ratio and line speed assessment, you will likely find that by leveraging your Variable Frequency Drive’s speed range, you can minimize the number of ratios needed on your reducers. Create a standard list of reducer case sizes along with ratios needed, optimizing gear reducer usage and reducing your inventory dollars.

The experts on saving money in inventory

Since 1991, STOBER has been saving our customers thousands of dollars in inventory, directly contributing to their bottom line. Our engineering team can evaluate your lines, simplify your reducer needs and optimize your storeroom.

Want to know more? Download the guide!